Tell Us About Your Project

Contact us

- Boise, Idaho

- (561) 714-6848

- sales@globalhavenschools.com

designed for schools

We specialize in custom-engineered steel school structures that offer rapid, reliable construction, ensuring that educational facilities are ready to support tomorrow’s learning, today.

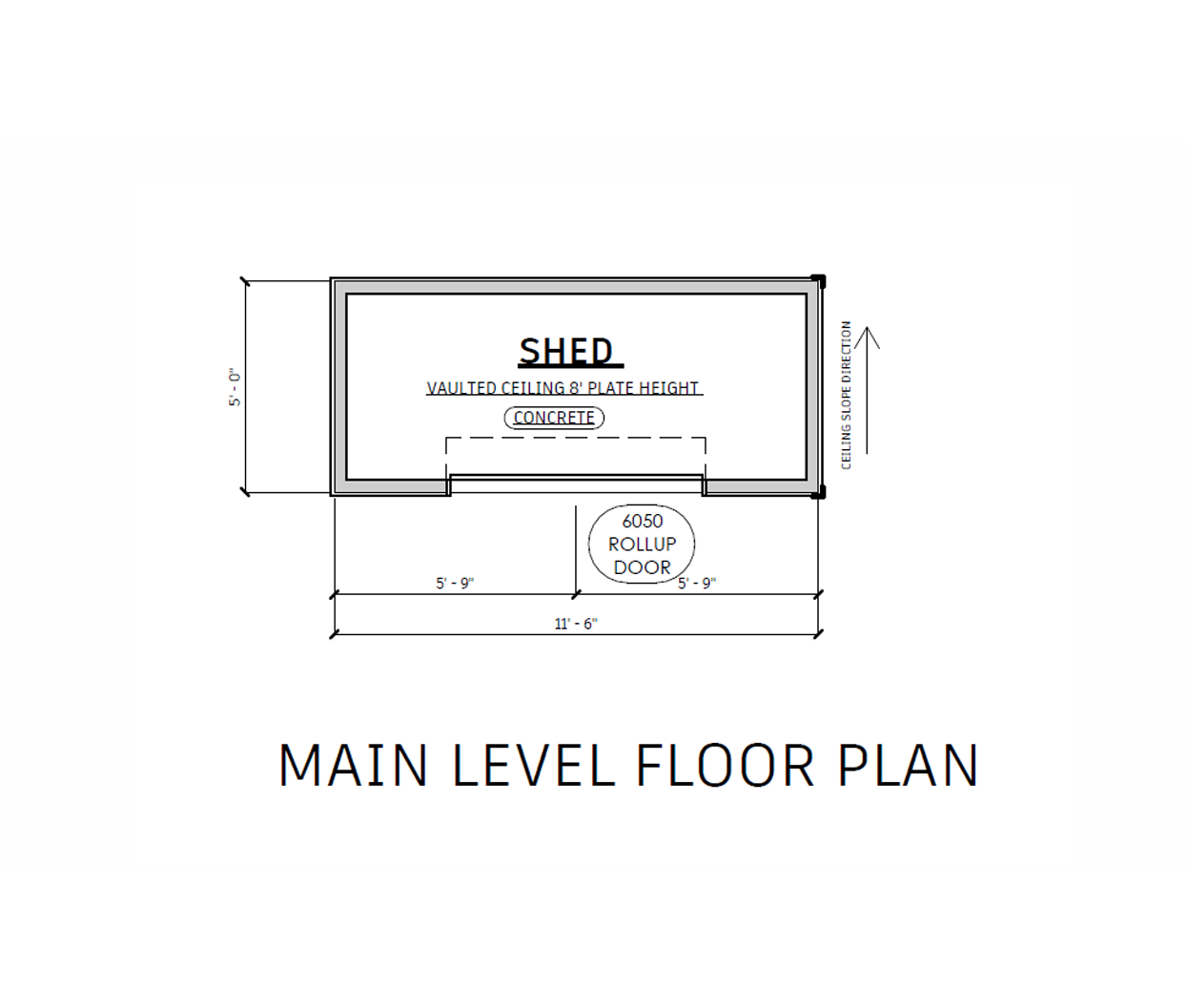

Affordability and quick construction timelines make our custom engineered steel structures a practical solution for schools looking to expand or upgrade their facilities. Designed with efficiency and durability in mind, these buildings are ideal for temporary classrooms/portables, sports and other educational facilities including; storage sheds, indoor batting cages and other athletic structures, perfect for meeting tight budgets and urgent timelines.

Our Light Gauge Steel Structures use light gauge steel as the main structural component.

Our specialization in school-specific structures means we understand how to build for durability, safety, and student use. Each project is customized to meet district codes, athletic requirements, and long-term functionality.

With streamlined fabrication processes and experienced field teams, we offer faster project completion without compromising quality—ideal for schools working around academic schedules.

Our portable classrooms, batting cages, and sheds are engineered for flexibility. Schools can easily repurpose or relocate structures based on evolving needs, saving time and money.

All builds meet or exceed local and national safety standards, including wind, seismic, and fire codes. We prioritize secure, kid-safe materials and finishes suitable for school environments.

We work hand-in-hand with school districts, architects, and contractors—offering transparent timelines, budgeting, and progress updates to make projects stress-free from planning to install.

Over 25 years of commercial real estate and development experience. Owner of several development companies and other entrepreneurial enterprises.

25 plus years of financial & strategic leadership experience across several industries ranging from publicly traded fortune 100s to early-stage start-ups.

With over 30 years of experience in the construction industry, Larry has successfully led projects of all sizes and complexities. In addition to industry leadership, he has shared his knowledge as a Construction Management professor at Boise State University, helping to shape the next generation of construction professionals

Over 34 years of executive leadership and business growth by building successful sales organizations. Former Chief Sales & Marketing Officer of the #89 fastest growing company in the US ~INC 500.